Today we’re discussing Options to Consider for Deep Frozen Applications and is part of your series on “How to Buy the Best Refrigerated Trailer.”

If you’re buying a reefer trailer to haul product at 0 to -20 degrees, and you have some questions about properly spec’ing it for deep-frozen, then you’re at the place.

We’re going to learn about:

Read: “How to Buy the Best Reefer Trailer”

- How to determine your clearance needs and insulation options

- How alternative deep-frozen insulation options will allow for backhauling other product types

- Spec’ing the correct reefer unit for deep-frozen

- And other options to consider

Carefully spec’ing your reefer trailer for frozen food is vital. The right insulation and reefer unit are critical components to keeping a 0 -20 consistent temperature.

Interior dimensions and insulation packages.

Determine your clearance needs and evaluate your options. Here’s why.

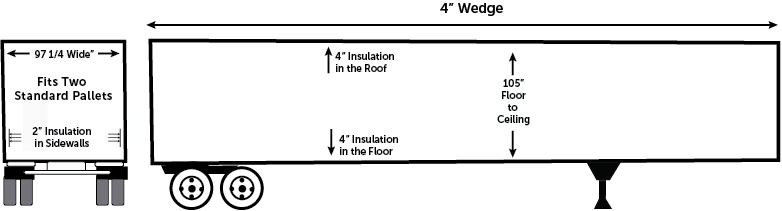

Standard Reefer Trailer Insulation includes:

- 2″ in the Side Walls

- 3″ in the Floor, and Ceiling

Insulation for Deep-Frozen Trailer applications.

- Add 1″ of insulation to the ceiling and floor if you’re hauling deep-frozen product to increase your reefer insulation factor for -20 and below.

- Upgrade to 4″ in insulation in the Floor, and Ceiling

Before adding another 1″ of insulation to your sidewalls, consider your backhaul opportunities.

- For every 1” of insulation you add, you will lose 2” of inside width and height.

- A standard reefer trailer with 2″ of sidewall insulation = 97 ¼ interior width (wearband to wearband). This dimension will fit (2) pallets with space left over.

- Adding another 1” to the sidewalls for the deep-frozen application will decrease your loading by 2 inches, limiting your backhaul opportunities.

Building a deep-frozen reefer trailer for various backhaul product types.

If you’re planning on hauling other types of product on your backhauls, you won’t be able to get a standard pallet in that trailer insulated for deep-frozen products.

Are you sure you want to do that? What happens if you’re in California needing to go back East, and produce is the only backhaul freight available?

Consider building your reefer trailer to haul both deep-frozen and produce or other general commodity products.

- 2″ insulations in the Side Walls to accommodate standard pallets.

- 4″ insulation in the Floor, and Ceiling.

- Add a 4″ Wedge to keep the 105″ floor to ceiling height.

By increasing insulation and using the wedge design, you gain versatility with various backhaul opportunities and increased earnings potential.

And, you won’t be building a white elephant.

Instead, the versatility of this reefer trailer can increase your ability to resell it in 5, 7, or 10 years.

Three more options to consider for hauling deep-frozen.

So, we’ve talked about clearance, insulation, backhauls, and wedge design. Let’s consider three more options:

- Paint the Roof White.

The first option is let’s paint your roof white that’s going to help deflect the sunlight and reduce the amount of heat that penetrates through the roof. - Upgrade Reefer Unit.

A high-capacity reefer unit rated at 64,000 BTUs, the Thermo King S-700 and the Carrier X4 7500 are designed to cool down your load faster and maintain minus 20 degrees for deep-frozen application. - Consider Data Track.

Data Track will give you a digital readout from point A to point B of how your unit performed and what temperature it held. And this is going to help eliminate any disputes from shippers.

* These options cost more upfront, however, they increase revenue and maintain trade-in value.

Read more in this series, How to Buy the Best Reefer Trailer.

- How to Buy the Best Reefer Trailer

- Spec’ing a High Cube Trailer

- Deep Frozen – Spec’s and Options

- Spec’ing a Reefer Trailer for Hauling Produce

- Standard Reefer Trailer Spec’s

Options and Upgrades to a Standard Reefer Trailer.

- Insulation, Lights, and Stainless Steel Options

- Wearband, Securement, and Side Panel Options

- Tires, Wheels, Suspension and Brake Options

- Heavy Haul Specs

- Lightweight Savings

Multi-Temp Design Strategies and Perspectives for Single Temp Operators.

- Temperature Ranges and Zones in a Multi-Temp

- Heat Evaporator – Placement and Airflow

- Multi-Temp Remote Control and Shore Power

- Dimensions of a Multi-Temp Trailer

- Driver Safety For Multi-Temp Operations

- Interior and Exterior Lighting

- Bulkheads and Dividers

- Product Safety Features

- Backhaul Restrictions